ROBOTICS

Augmenting Human Potential

UNLOCKING UNPRECEDENTED LEVELS OF PRODUCTIVITY

A SAFER, MORE ENGAGING WORKPLACE ENVIRONMENT

The robotics revolution is no longer a distant forecast; it is a present-day reality reshaping the landscape of modern business. For franchises, the integration of robotic technology represents a pivotal opportunity to gain a significant competitive edge. Beyond simple automation, robotics offers a pathway to fundamentally re-engineer core business processes, from manufacturing and logistics to customer service and quality control.

By deploying robotic systems, franchises can achieve unprecedented levels of precision, speed, and consistency, directly translating to enhanced product quality and a more reliable customer experience. This technological shift allows franchise owners to transcend traditional operational limitations and unlock new potentials for growth and market leadership.

In the franchise model, where brand consistency and operational uniformity are paramount, robotics provides the ultimate tool for standardization. Human error, a variable that can lead to inconsistencies across different franchise locations, is virtually eliminated in tasks handled by robotic systems. Whether it’s a robotic arm perfectly assembling a product, an autonomous mobile robot (AMR) navigating a warehouse to fulfill orders, or a customer-facing kiosk providing flawless service, the result is an operation that can be replicated with near-perfect fidelity across the entire franchise network. This ensures that every customer, regardless of location, receives the same high-quality experience that your brand promises.

REALLOCATE HUMAN CAPITAL

The economic implications of integrating robotics are profoundly compelling. While the initial investment can be significant, the long-term return on investment is driven by substantial reductions in operational costs. Robots can operate around the clock without fatigue, drastically increasing productivity and output without the corresponding labor costs. They also contribute to a safer working environment by taking over tasks that are repetitive, strenuous, or hazardous, reducing workplace injuries and associated liabilities. This optimization of resources allows franchises to reallocate human capital towards more strategic, value-added roles such as customer engagement, innovation, and business development.

A 2025 study by the Manufacturing Institute found that integrating collaborative robots can increase overall production efficiency by up to 30% while simultaneously reducing workplace injuries by over 70%.

Currently, a number of Chinese companies are accelerating humanoid robot trials across various industries. Manufacturing giant Foxconn and Shenzhen-based humanoid robot company UBTECH announced on January 15, 2025 that the two companies will form a partnership to incorporate UBTECH’s humanoid robots into Foxconn’s intelligent manufacturing process.

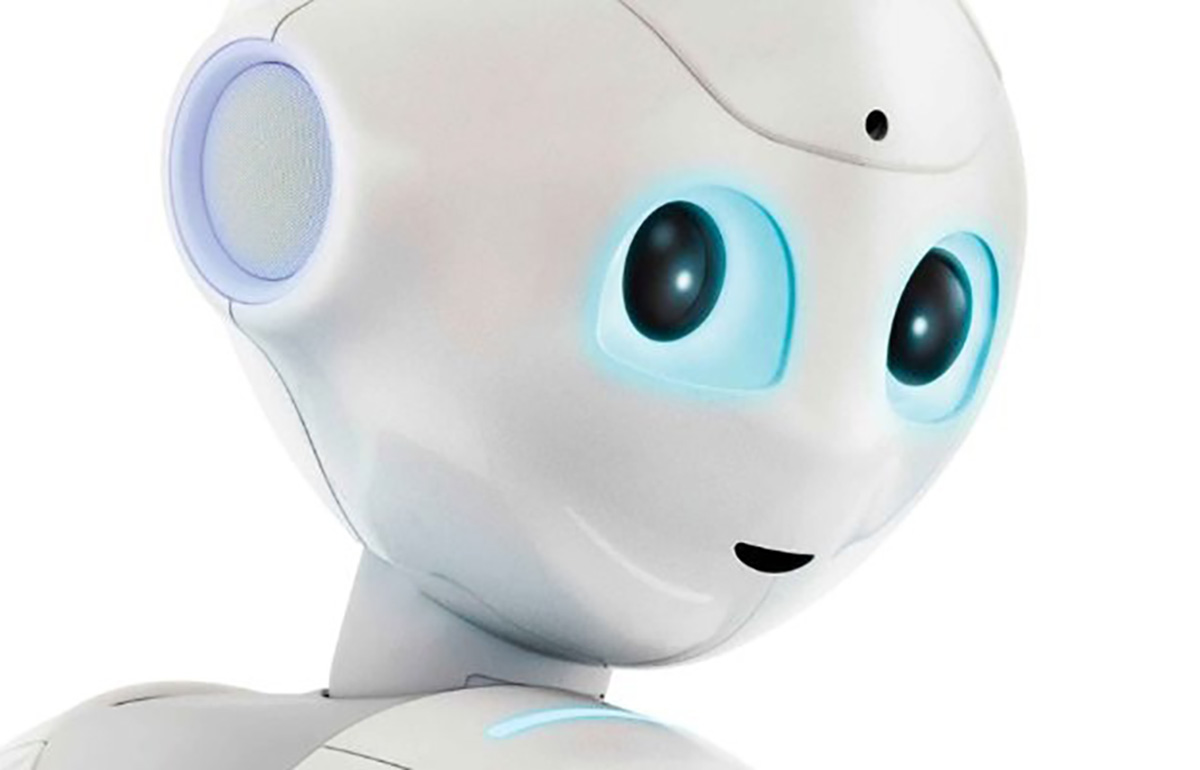

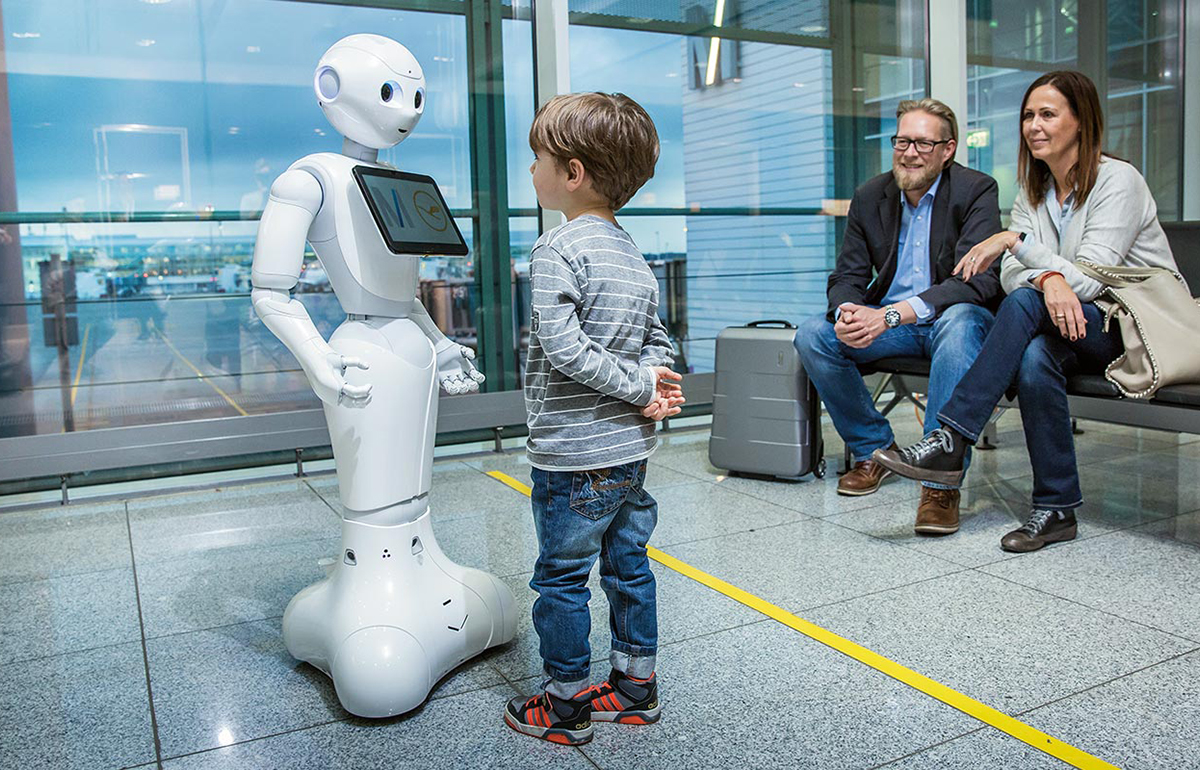

SOFTBANK ROBOTICS | PEPPER SERVICE ROBOT

An advanced humanoid robot designed for customer service, retail assistance, and human interaction. Pepper features emotion recognition, natural conversation capabilities, and autonomous navigation.

| SPECIFICATION | DETAILS |

|---|---|

| Height | 120 cm (47.2 inches) |

| Weight | 28 kg (61.7 lbs) |

| Battery Life | 12+ hours continuous operation |

| Sensors | 3D camera, 4 microphones, touch sensors, gyroscope |

| Mobility | Omnidirectional wheels, autonomous navigation |

| Connectivity | Wi-Fi, Ethernet, Bluetooth |

SOFTBANK ROBOTICS | PEPPER SERVICE ROBOT

Advanced humanoid robot for customer service and retail environments.

Inquire to arrange a product demo consultation.

SOFTBANK ROBOTICS | PEPPER COMPANION ROBOT

Advanced humanoid companion robot designed for customer service, retail assistance, and emotional interaction. Features emotion recognition, natural conversation capabilities, and autonomous navigation.

| SPECIFICATION | DETAILS |

|---|---|

| Height | 1.2m (4 feet) |

| Weight | 28 kg (62 lbs) |

| Battery Life | 12+ hours continuous operation |

| Mobility | Omnidirectional wheels |

| Interaction | Emotion recognition, voice, touch |

| Applications | Retail, hospitality, eldercare |

SOFTBANK ROBOTICS | PEPPER COMPANION ROBOT

Advanced humanoid companion robot for service applications.

Inquire to arrange a product demo consultation.

UNIVERSAL ROBOTS | UR10e INDUSTRIAL AUTOMATION ROBOT

High-precision, heavy-duty collaborative industrial robotic arm designed for industrial automation and manufacturing applications. Features advanced safety systems and easy programming interface for manufacturing automation.

| SPECIFICATION | DETAILS |

|---|---|

| Reach | 1300 mm (51.2 inches) |

| Payload | 12.5 kg (27.6 lbs) |

| Repeatability | ±0.05 mm |

| Degrees of Freedom | 6 rotary joints |

| Programming | Intuitive touchscreen interface |

| Safety Features | Collaborative operation, force sensing |

UNIVERSAL ROBOTS | UR10e INDUSTRIAL AUTOMATION ROBOT

High-precision, heavy-duty collaborative industrial robotic arm with 10kg payload capacity.

Inquire to arrange a product demo consultation.

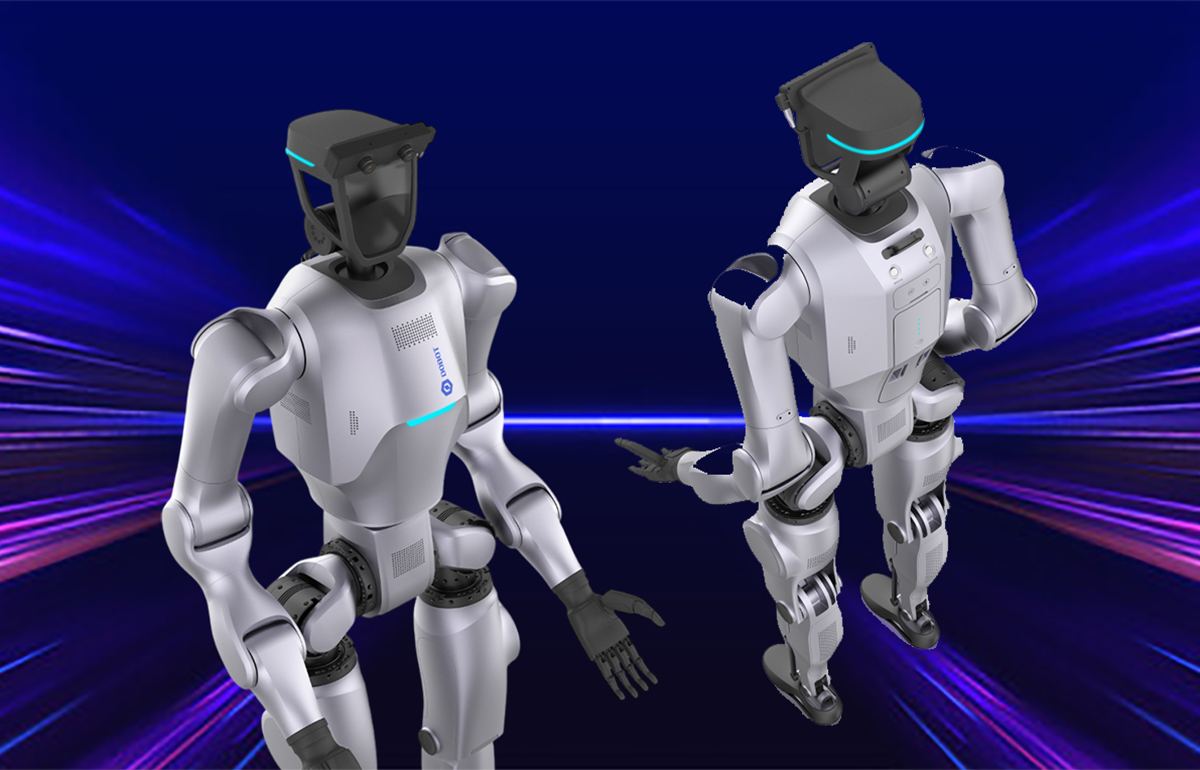

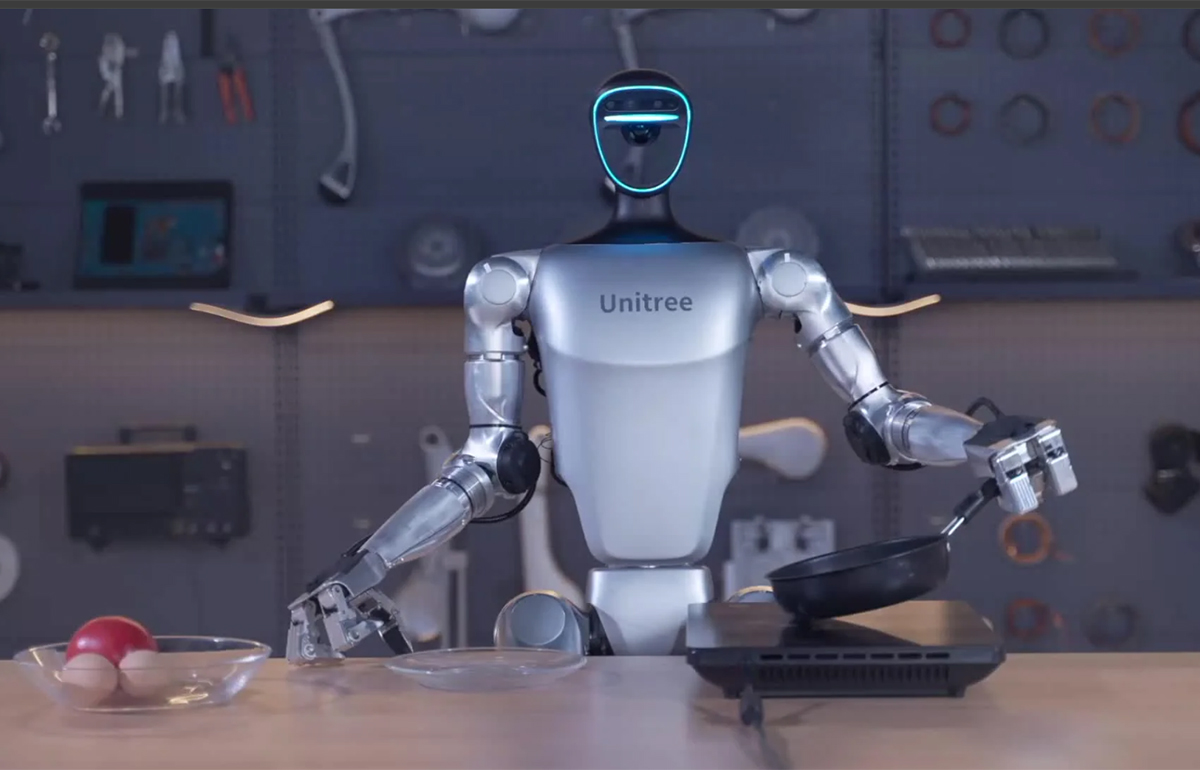

UNITREE ROBOTICS | G1 STANDARD

Advanced bipedal humanoid robot designed for research, demonstration, and basic interaction. Features 23 degrees of freedom, voice commands, and impressive mobility capabilities.

| SPECIFICATION | DETAILS |

|---|---|

| Height | 1.3m (4.3 feet) |

| Weight | 35 kg (77 lbs) |

| Degrees of Freedom | 23 DOF total |

| Mobility | Bipedal walking |

| Voice Commands | Basic voice interaction |

| Applications | Research, demonstration, education |

UNITREE ROBOTICS | G1 STANDARD

Advanced bipedal humanoid robot for research and demonstration.

Inquire to arrange a product demo consultation.

UNITREE ROBOTICS | G1 EDU STANDARD

Educational humanoid robot platform with advanced capabilities for research and development. Features comprehensive SDK, enhanced sensors, and full programming access.

| SPECIFICATION | DETAILS |

|---|---|

| Height | 1.3m (4.3 feet) |

| Weight | 35 kg (77 lbs) |

| Enhanced Sensors | Advanced sensor package |

| SDK Access | Full SDK and programming tools |

| Programming | Python, C++, ROS support |

| Applications | Research, education, development |

UNITREE ROBOTICS | G1 EDU STANDARD

Educational humanoid robot with full development capabilities.

Inquire to arrange a product demo consultation.

UNITREE ROBOTICS | H1 ADVANCED HUMANOID

Advanced bipedal humanoid robot designed for research and industrial applications. Features superior mobility, advanced AI capabilities, and robust construction for demanding environments.

| SPECIFICATION | DETAILS |

|---|---|

| Height | 1.8m (5.9 feet) |

| Weight | 47 kg (104 lbs) |

| Max Speed | 5.5 km/h walking |

| Degrees of Freedom | High mobility joints |

| Applications | Research, industrial, security |

| Construction | Robust industrial-grade materials |

UNITREE ROBOTICS | H1 ADVANCED HUMANOID

Advanced bipedal humanoid robot for research and industry.

Inquire to arrange a product demo consultation.

UNITREE ROBOTICS | H1-2 NEXT-GEN HUMANOID

Next-generation bipedal humanoid robot representing the latest in robotics technology. Features enhanced AI, improved mobility, and advanced manipulation capabilities for cutting-edge applications.

| SPECIFICATION | DETAILS |

|---|---|

| Generation | Next-generation humanoid |

| AI Capabilities | Enhanced artificial intelligence |

| Mobility | Advanced bipedal locomotion |

| Manipulation | Improved dexterous capabilities |

| Technology | Latest robotics innovations |

| Applications | Cutting-edge research, industry |

UNITREE ROBOTICS | H1-2 NEXT-GEN HUMANOID

Educational humanoid robot with full development capabilities.

Inquire to arrange a product demo consultation.

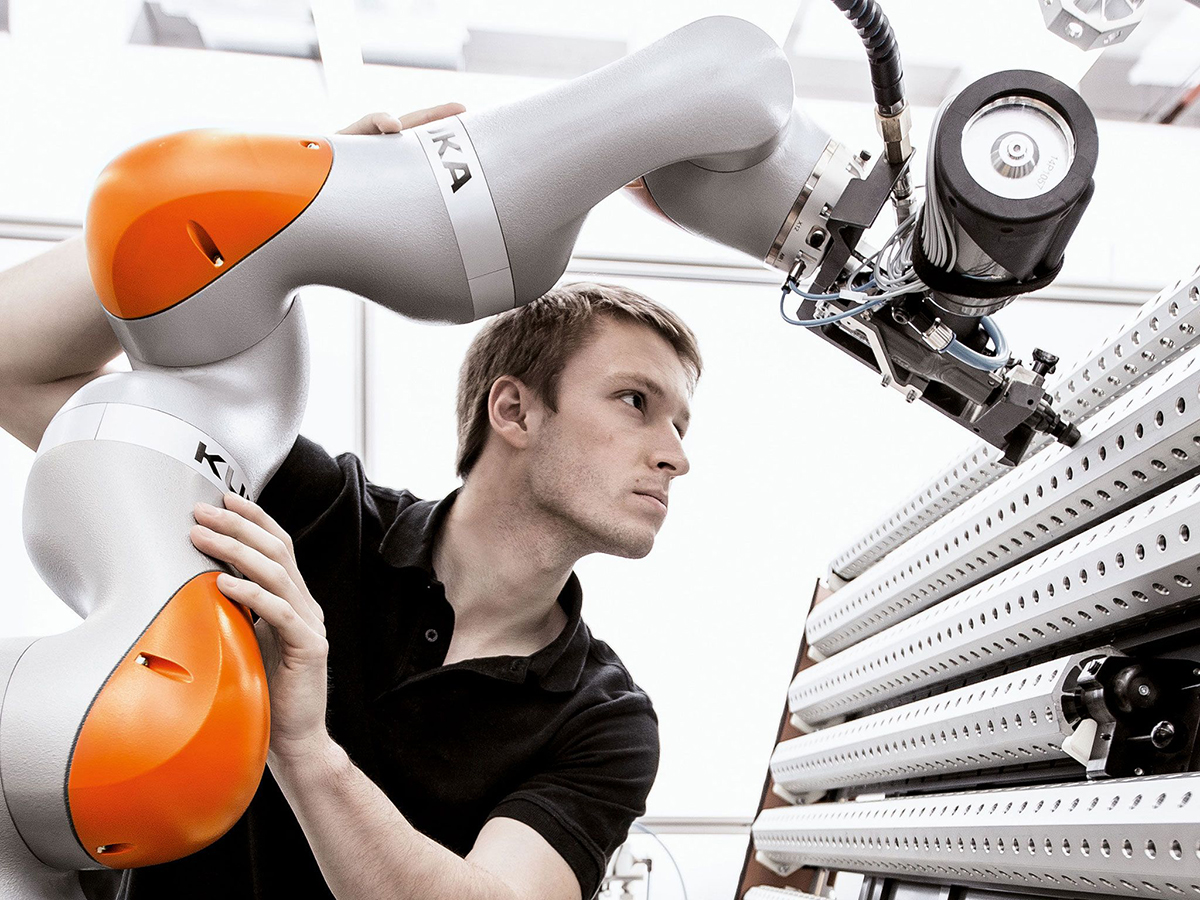

KUKA ROBOTICS | LBR IIWA 7 R800 INDUSTRIAL ROBOTIC ARM

Lightweight collaborative robotic arm designed for human-robot collaboration in manufacturing environments. Features 7 degrees of freedom, advanced safety systems, and precise manipulation capabilities.

| SPECIFICATION | DETAILS |

|---|---|

| Degrees of Freedom | 7 DOF |

| Payload | 7 kg maximum |

| Reach | 800mm radius |

| Repeatability | ±0.1mm |

| Safety | Integrated safety systems |

| Applications | Assembly, inspection, handling |

KUKA ROBOTICS | LBR IIWA 7 R800 INDUSTRIAL ROBOTIC ARM

Collaborative robotic arm for precision manufacturing applications.

Inquire to arrange a product demo consultation.

OMRON ROBOTICS | LD-250 AUTONOMOUS MOBILE ROBOT

Autonomous mobile robot designed for material transport and logistics applications. Features advanced navigation, obstacle avoidance, and fleet management capabilities.

| SPECIFICATION | DETAILS |

|---|---|

| Payload | 250 kg maximum |

| Max Speed | 1.8 m/s |

| Navigation | Autonomous navigation |

| Battery Life | 8+ hours continuous operation |

| Safety | 360° laser scanner, safety bumpers |

| Applications | Material transport, logistics |

OMRON ROBOTICS | LD-250 AUTONOMOUS MOBILE ROBOT

Autonomous mobile robot for material transport and logistics.

Inquire to arrange a product demo consultation.

DOBOT ROBOTICS | ATOM TRAINER RESEARCH HUMANOID

Advanced humanoid AI platform designed for research and development. Features 29 degrees of freedom, comprehensive AI capabilities, and extensive programming options for advanced robotics research.

| SPECIFICATION | DETAILS |

|---|---|

| Degrees of Freedom | 29 DOF total |

| AI Platform | Advanced machine learning capabilities |

| Programming | Multiple programming languages |

| Research Focus | AI development and training |

| Mobility | Bipedal walking and manipulation |

| Applications | Research, education, AI development |

DOBOT ROBOTICS | ATOM TRAINER RESEARCH HUMANOID

Autonomous mobile robot for material transport and logistics.

Inquire to arrange a product demo consultation.

DOBOT ROBOTICS | ATOM MAX ADVANCED RESEARCH HUMANOID

Maximum capability humanoid robot designed for advanced research and industrial applications. Features the highest level of AI integration, mobility, and manipulation capabilities available.

| SPECIFICATION | DETAILS |

|---|---|

| Capability Level | Maximum performance configuration |

| AI Integration | Highest level AI capabilities |

| Mobility | Advanced bipedal locomotion |

| Manipulation | Maximum dexterity and precision |

| Research Platform | Ultimate research and development tool |

| Applications | Advanced research, industrial automation |

DOBOT ROBOTICS | ATOM MAX ADVANCED RESEARCH HUMANOID

Maximum capability humanoid robot for advanced applications.

Inquire to arrange a product demo consultation.

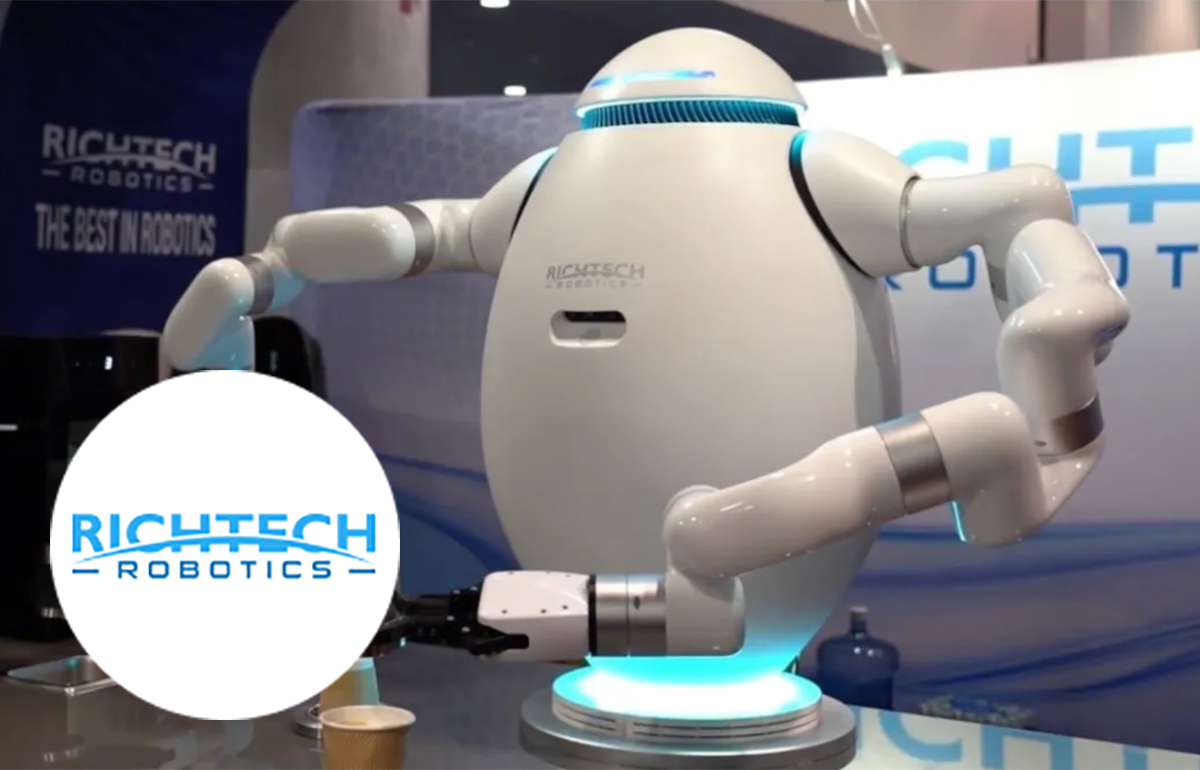

Richtech | ADAM COLLABORATIVE ROBOT

| SPECIFICATION | DETAILS |

|---|---|

| Payload | 10 kg maximum |

| Reach | 1300mm radius |

| Repeatability | ±0.05mm |

| Weight | 33.5 kg |

| Programming | Intuitive teach pendant |

| Applications | Heavy lifting, palletizing, welding |

Richtech | ADAM COLLABORATIVE ROBOT

Specialized robotic system that automates drink preparation with precision and flair.

Inquire to arrange a product demo consultation.

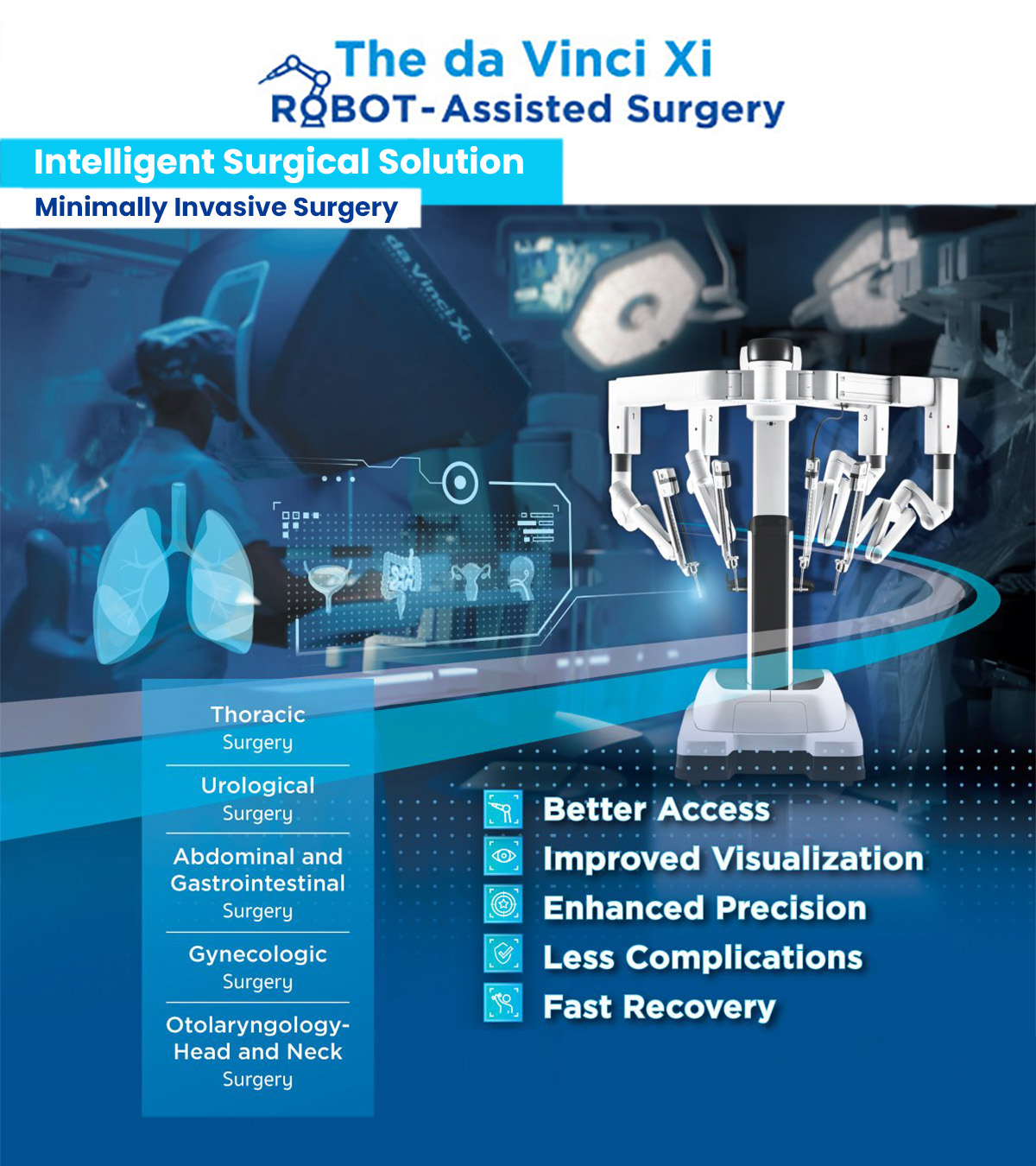

INTUITIVE SURGICAL | DA VINCI XI INTELLIGENT SURGICAL SOLUTION

Advanced surgical robot system providing minimally invasive surgery capabilities with enhanced precision, control, and visualization for medical procedures.

| SPECIFICATION | DETAILS |

|---|---|

| Arms | 4 robotic arms with EndoWrist instruments |

| Vision System | 3D HD stereoscopic visualization |

| Precision | Motion scaling and tremor filtration |

| Instruments | Over 60 different surgical instruments |

| Control | Surgeon console with hand controls |

| Applications | General, cardiac, gynecologic, urologic surgery |

INTUITIVE SURGICAL | DA VINCI XI INTELLIGENT SURGICAL SOLUTION

State-of-the-art surgical robot system for minimally invasive procedures.

Inquire to arrange a product demo consultation.

AUTOMATING KEY PROCESSES

Robotics enable your organization to realize a more resilient, efficient, and scalable business model that can adapt to fluctuating labor markets and changing customer demands. Brand Factory can provide your team with strategic expertise and technical integration solutions that can ensure your planned robotics initiative is not just a capital expenditure, but a transformative investment that delivers a powerful and lasting competitive advantage.

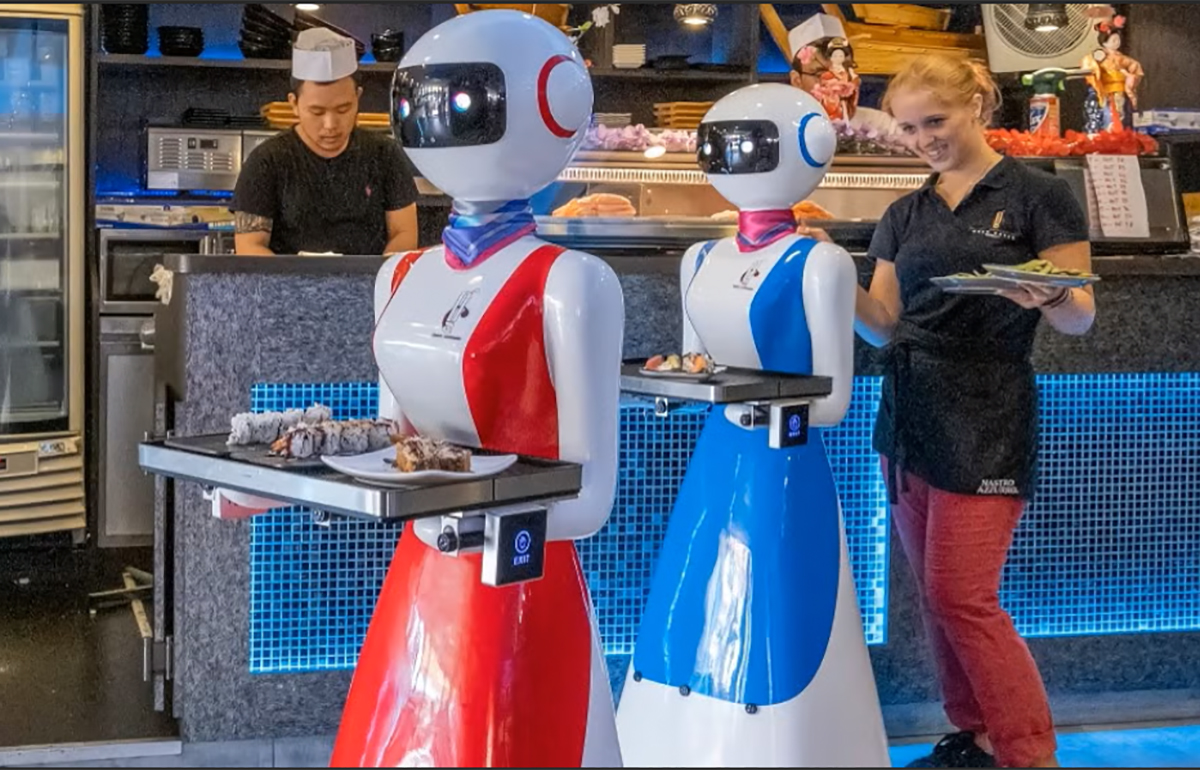

ROBOTICS IN RETAIL: ROBOT CHEFS

The versatility of modern robotics means that solutions can be tailored to the specific needs of virtually any franchise industry. For quick-service restaurants, robotic chefs can prepare meals with perfect consistency and timing, ensuring food quality and reducing wait times. In the retail sector, autonomous systems can manage inventory, restock shelves, and provide in-store assistance, freeing up human staff to focus on creating a superior customer shopping experience. For service-based franchises, such as cleaning or maintenance, robotic equipment can perform tasks with a level of efficiency and thoroughness that is difficult to achieve manually.

ROBOTICS IN LOGISTICS

In logistics, advanced humanoid robotic systems can operate around the clock with near-perfect accuracy, dramatically reducing order fulfillment times and eliminating costly shipping errors. By automating key processes, you are not replacing the human element but elevating it, allowing your team to focus on what they do best: building relationships and driving the business forward.

RETAIL & RESTAURANT COMMERCE

Robotics are increasingly used in both retail and restaurant commerce to boost efficiency, improve customer service, and address labor shortages. Robots are deployed for a variety of functions, from customer-facing service to behind-the-scenes operations like inventory management and food preparation. By automating repetitive, dangerous, or time-consuming tasks, robots free up human staff to focus on more complex, creative, and customer-facing roles.

ROBOTICS IN RETAIL: BACK-OF-HOUSE & E-COMMERCE FULFILLMENT

Major retailers like Walmart, Amazon, and Kroger have integrated robotics throughout their operations, from warehouses to store floors. The uses can be divided into back-of-house logistics and front-of-store automation.

These systems use robotic shuttles and containers to efficiently manage inventory in compact spaces, enabling micro-fulfillment centers within or near stores. Companies like Ocado sell automated warehousing systems to retailers, where robots can store, retrieve, and transport products efficiently.

ROBOTICS IN RETAIL: IN-STORE OPERATIONS

Autonomous mobile shelf scanning robots (AMR’s), like Simbe Robotics’ Tally, patrol store aisles to scan shelves using cameras and sensors. They monitor stock levels, identify out-of-stock items, correct misplaced products, and check for inaccurate pricing. This provides accurate, real-time inventory data that helps retailers optimize merchandising and fulfillment. This improves accuracy and frees up human staff.

RESTAURANT ROBOTICS: BACK-OF-HOUSE AUTOMATION & FOOD PREPERATION

Faced with labor shortages and rising costs, restaurants are deploying robotics to automate back-of-house tasks and expedite front-of-house service.

RESTAURANT ROBOTICS: FRONT-OF-HOUSE & DELIVERY

Robots like Richtech Robotics’ Matradee and Bear Robotics’ autonomous service robots serve as "support staff" by delivering food from the kitchen to customers’ tables or bussing dirty dishes — allowing human waitstaff to focus on customer interaction. This increases human servers’ time for customer interactions, potentially boosting tips.

In an increasingly crowded marketplace, this technological differentiation can be a key factor in attracting both customers and potential franchisees. Consumers are drawn to brands that are efficient and modern, while prospective investors are looking for franchise opportunities that are built on a sustainable and future-proof business model.

Integrating robotics demonstrates a commitment to staying ahead of industry curves and a readiness to embrace the future of commerce. The strategic integration of robotics is about more than just improving efficiency; it’s about building a more resilient, scalable, and competitive franchise.

DISCOVER ROBOTIC AUGMENTATION THAT MAKES SENSE

As we move into an era defined by technological advancement, the organizations that embrace robotics will be the ones that not only survive but thrive, setting new standards for their industries and delivering unparalleled value to their customers. Our goal is to help our clients realize these gains by selecting the right hardware and embedding it seamlessly into your existing processes. The key to a successful robotics initiative is interoperability. A robot is only as effective as the data ecosystem it operates within.

The adoption of robotics is a clear and powerful signal to the market that your franchise is forward-thinking and committed to innovation. Our role is to act as your strategic partner in this transformation. We help you navigate the complex landscape of robotics hardware, from affordable customer-facing units to high-end industrial manufacturing systems. We don’t just sell robots; we architect integrated solutions. This begins with a deep operational analysis to identify the precise workflows where robotic augmentation will deliver the highest ROI.

| ROBOTIC SYSTEM | PRIMARY ROI & KEY SALES POINTS |

|---|---|

| Unitree H1: | High-End Capability at an Entry-Level Cost. Delivers advanced dynamic mobility and strength for logistics and inspection tasks, providing the ROI of a high-end system with a significantly lower capital investment. |

| Agility Robotics Digit: | Warehouse & Logistics Game-Changer. Designed specifically for "last-mile" logistics within a warehouse. Directly augments human workers by moving totes and packages, increasing fulfillment speed and reducing physical strain on employees. |

| Apptronik Apollo: | The Collaborative Generalist. A friendly, human-centric design makes it ideal for working alongside humans in manufacturing and retail. Its versatility allows it to be deployed across multiple tasks, maximizing utilization and ROI. |

| Sanctuary AI Phoenix: | The Fine-Motor Skills Specialist. Unparalleled hand dexterity allows it to perform complex assembly and manipulation tasks previously impossible for robots. Reduces errors and increases throughput in detailed, high-value production lines. |

| Figure 01: | The Autonomous Worker. Aims to be a fully autonomous humanoid capable of learning and performing a wide range of tasks. The ultimate solution for addressing labor shortages and creating a 24/7/365 operational capability. |

| Boston Dynamics Atlas: | The Pinnacle of Dynamic Mobility. The most agile and powerful humanoid available. Ideal for R&D and tackling the most extreme physical challenges, pushing the boundaries of what’s possible in automation. |

| Promobot V.4: | Affordable Customer Engagement. A cost-effective solution for deploying an interactive, data-collecting presence in retail, banking, or event settings. Increases customer engagement and frees up staff for complex sales. |

| UBTECH Walker S: | Advanced Service & Mobility. A bipedal robot that offers a more human-like interaction than wheeled models. Perfect for premium hospitality or corporate environments to guide visitors and perform service tasks. |

| Engineered Arts Ameca: | The Ultimate Human-Like Interaction. The world’s most advanced expressive face creates unparalleled human-robot connection. Ideal for entertainment, brand ambassadorship, and research into human-computer interaction. |

| Richtech ADAM: | The Robotic Bartender/Barista. A specialized system that automates drink preparation with precision and flair. Increases service speed, ensures consistency, and creates a unique customer experience that drives traffic. |

| SoftBank Robotics Pepper: | Proven & Recognizable Engagement Platform. A globally recognized humanoid designed for customer interaction. Its established platform and developer ecosystem make it a reliable choice for retail and educational applications. |

| PAL Robotics ARI: | Compact & Customizable Social Robot. A smaller, more accessible social robot with a focus on customizability. Its open platform allows for tailored solutions in healthcare, reception, and research at a lower price point. |

We specialize in creating the software bridge that connects your robotic workforce to your core business systems — your inventory management, your point-of-sale, your CRM, and your supply chain logistics. This level of integration allows for real-time data exchange, enabling robots to perform tasks with up-to-the-minute accuracy, from retrieving the correct inventory item to providing a customer with their precise order status. This level of integration transforms a standalone robot from a novelty into a fully-fledged, data-driven member of your operational team.